Description

Introduction

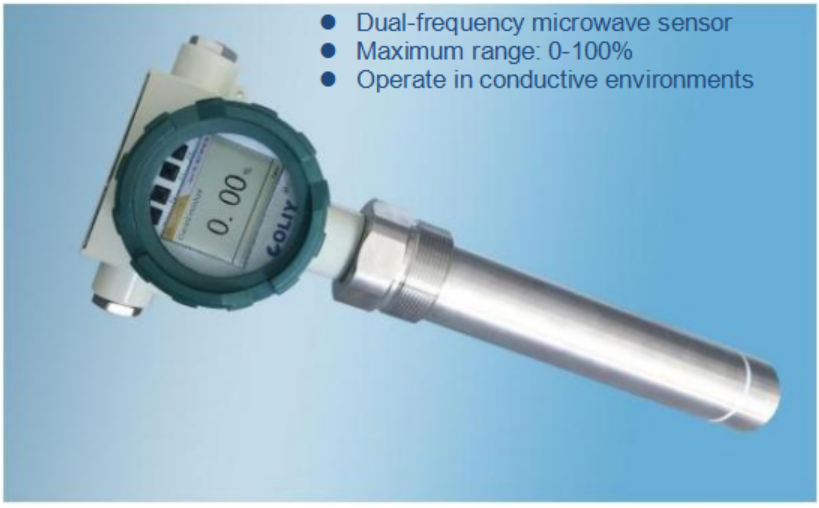

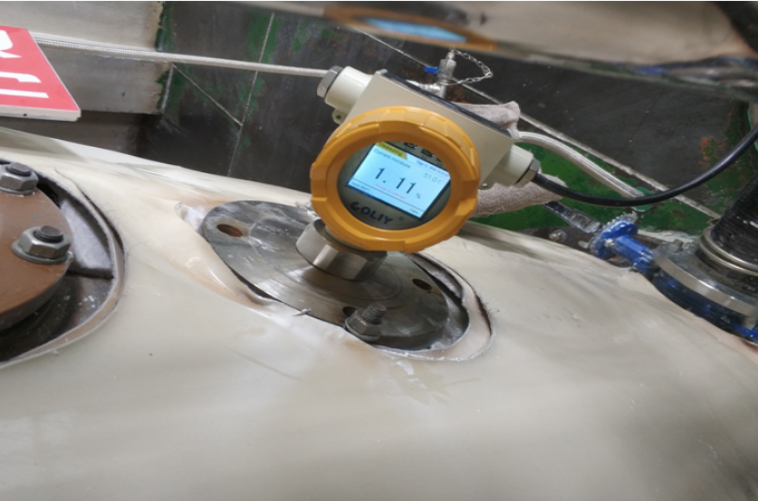

The S300 Online Moisture Analyzer is an intelligent, high-precision industrial moisture detection instrument primarily designed for measuring the moisture content in solids and liquids. Its large, flat bottom ensures optimal contact with solid materials. Equipped with COLIY’s patented dual-antenna microwave moisture sensor, the S300 can detect moisture levels ranging from 0% to 100% and operates effectively in slightly acidic, alkaline, or other conductive environments. It covers a wide range of applications, including solids, slurries, and even liquids, thereby enhancing the versatility of moisture detection.

The S300 Online Analyzer features a fully sealed, integrated structure with no mechanical moving parts. The sensor is seamlessly integrated into the probe, which is cylindrical with a smooth surface to prevent clogging by solid materials. Designed to industrial standards, the S300 has a maximum range of 0-100%, a display resolution of up to 0.01%, a probe temperature resistance of up to 120°C, and a pressure resistance of up to 1MPa. Advanced data storage technology ensures data retention even after power loss.

The probe includes a high-precision temperature sensor for accurate temperature compensation via proprietary calibration software. The S300 is insensitive to material color and can measure most weakly conductive media. Microwave measurement technology offers depth detection, penetrating the medium for more accurate results compared to surface-based methods like infrared detection.

The S300 Online Moisture Analyzer is CE-certified.

Typical Applications

The S300 Insertion Online Moisture Analyzer is widely used in industries such as grain and feed, construction materials, coal, pharmaceuticals, food, daily chemicals, paper, tobacco, metallurgical sintering, petroleum and petrochemicals, textiles, power, and chemicals.

The stability of grain storage is influenced by both temperature and moisture. Proper control of these factors can inhibit the growth of mold, mites, and insects, preventing damage to stored grain. Moisture detection is critical for grain procurement, transportation, storage, processing, and trade.

In steel production, iron ore is typically crushed at mines and mixed with water to form slurry. This slurry is transported over long distances via pipelines to steel plants. Moisture content plays a vital role in pipeline transportation—too low and the pipeline may clog; too high and efficiency drops. Monitoring slurry moisture is therefore essential.

Moisture measurement is required throughout crude oil extraction, pipeline transportation, and refining processes. COLIY’s Online Moisture Analyzer provides solutions for oil extraction, pipeline transportation, integrated stations, trade transfer, and refining operations.

Features

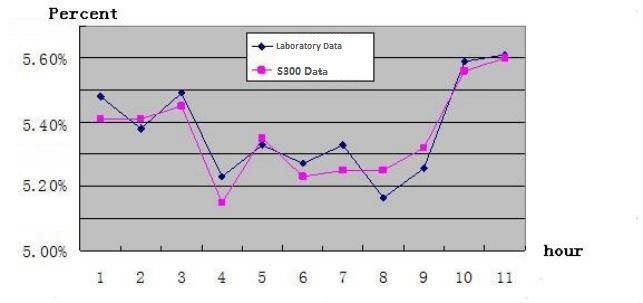

The S300 Online Moisture Analyzer, developed by COLIY, delivers long-term measurement data comparable to laboratory results, meeting precision requirements.

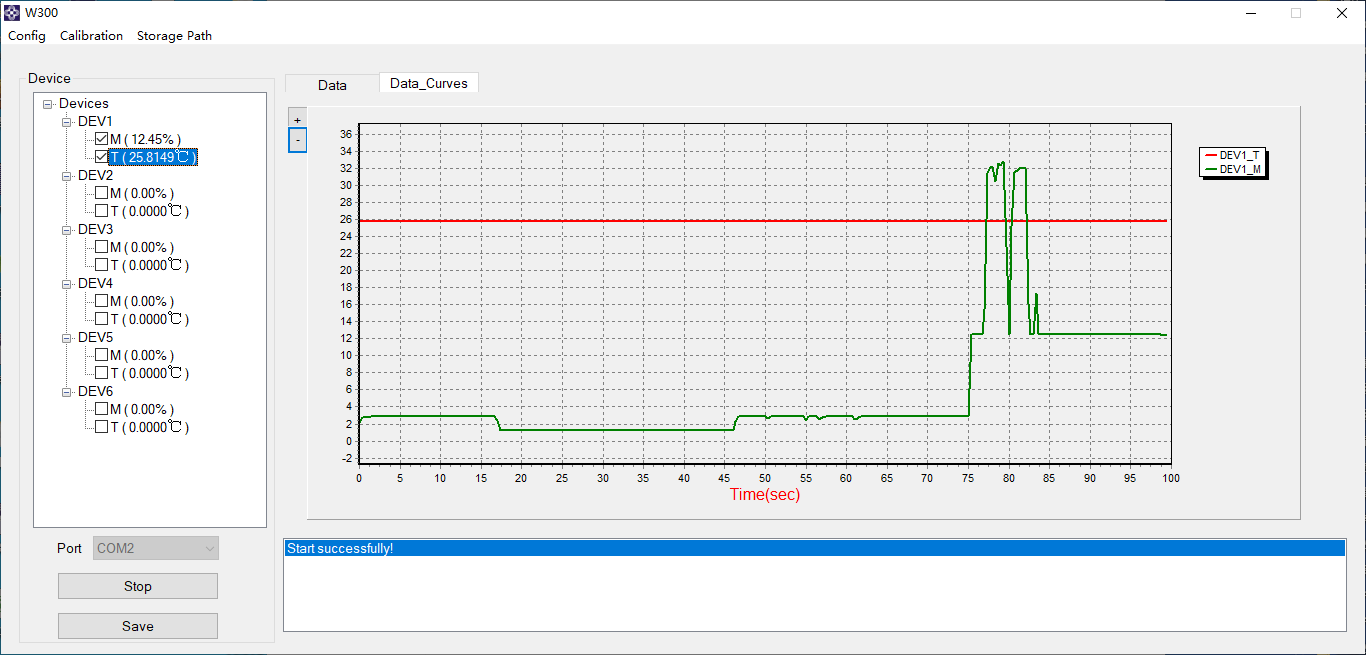

Intelligent PC Software

The software offers robust functionality: simultaneous calibration and display for multiple analyzers, automatic recording and graphing, real-time display of medium temperature, current moisture value, and average value, remote calibration and settings, and export of moisture measurement data.

Typical Installation

(1) Installation

Bottom Installation |

Side Installation |

The probe must protrude at least 8CM. Avoid installation near the feed inlet to reduce impact damage. If the analyzer must be near the inlet, install a protective baffle above it.

Moisture detection in quartz sand hoppers at glass factories

Specifications

| Parameter | Description |

| Range | Model S300: 0-30% Model S300H: 0-100% |

| Typical accuracy | 0.1% (range <10%) 0.5% (range >10%) 1% (range >50%) |

| Installation Method | 2-inch NPT thread or standard flange |

| Insertion Depth | Standard 245mm or custom length upon request |

| Weight | Approx. 5KG (standard length and threaded installation) |

| Max. Probe Temperature | Standard: <80°C High-temperature: <120°C Above 120°C: Contact manufacturer |

| Temperature Compensation | Yes (required for large temperature variations in the medium) |

| Probe Material | 304 stainless steel (optional: 316L stainless steel or titanium) |

| Explosion-proof Rating | Ex d IICT6 (optional) |

| Output | RS485 and 4-20mA |

| Power Supply | Wide voltage 9V-36VDC (recommended: 24VDC) |

| Pressure Rating | Standard: <0.2MPa High-pressure: <1MPa |

| Microwave Frequency | 1GHz, 6.8GHz |

| Sampling Frequency | 1000 times/second |

| Protection Rating | IP68 |

| Recommended Calibration | 12 months |

| Display | Date, time, moisture value, AD value, calibration table number |

| Temperature Sensor | Imported digital temperature sensor |

Model Selection Table

Example:S300-HI-F-316

Reviews

There are no reviews yet.