XgardIQ

The new XgardIQ, our most intelligent fixed-point gas detector, increases safety by minimising the time operators must spend hazardous areas.

This versatile transmitter and gas detector has a range of features that protect engineers and support facilities managers of oil, gas, chemical & petrochemical plants to name a few.

Available fitted with a variety of flammable, toxic or oxygen gas sensors

- Description

Product Description

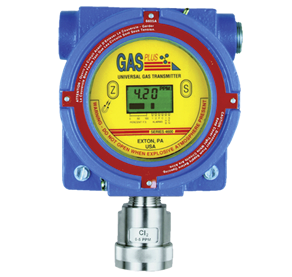

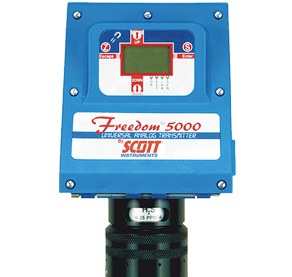

XgardIQ is an intelligent and versatile gas detector and transmitter compatible with Crowcon’s full range of sensor technologies. Available fitted with a variety of flammable, toxic or oxygen gas sensors.

Providing analogue 4-20mA and RS-485 Modbus signals as standard, XgardIQ is optionally available with Alarm and Fault relays and HART communications. The 316 stainless steel are available with three M20 or 1/2“NPT cable entries.

Easy and safe to use

- OLED display – Bright, clear display indicates gas level and detector status even in dark locations

- Non-intrusive calibration – Zero and calibration functions are performed via the display and keypad, without the need for a hot-work permit or any special tools (e.g. no magnetic wand required)

- +ve Safety indicator – Confirms the detector is operating safely at a glance

- Event log function – Stores all alarm, fault and maintenance events to provide a history of detector use

Simple installation and maintenance

- Universal transmitter – Common transmitter for Crowcon’s full range of sensor technologies

- Hot-swap sensor modules – Sensors can easily be replaced using one hand without requiring tools or a hot-work permit

- Auto-sense function – Automatically detects whether the control system is 4-20mA current sink or source and sets itself appropriately, eliminating the risk of being incorrectly set

- Auto-configure function – Detects when a sensor module is plugged-in and uploads the appropriate gas type, range, units and alarm levels

Reliability

- Smart Bump and Speedy Bump test functions – Enable sensor health and response to be verified quickly and easily using test gas. Process is automated and provides a reminder when a bump test is due

- Calibration due warning – Reminds the user when calibration is due to ensure that sensors remain operational and accurate at all times

- Sensor range selection – User can set the full-scale range of the sensor via the display menu according to site or specific location requirements